- PHONE 02476 447 431

- EMAIL info@auric.co.uk

-

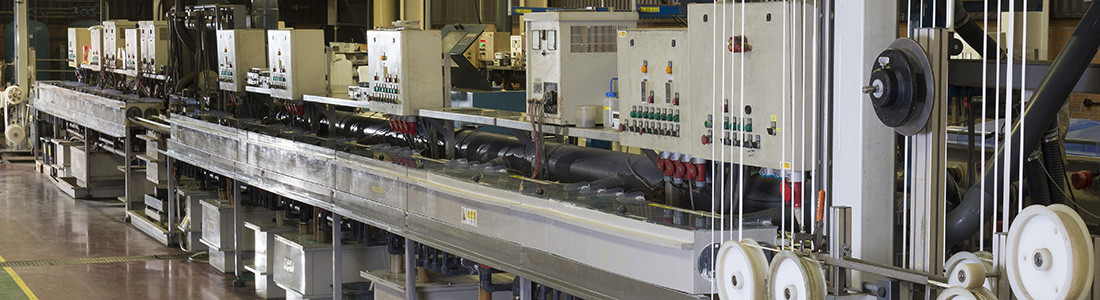

Our reel to reel plating facilities use advanced technology to apply coats of copper, gold, nickel, palladium, silver and pure tin precisely and economically.

This enables us to rapidly plate high volumes of metal strip from a spool, with minimum waste and maximum cost-effectiveness.

Operating at up to 20 metres a minute, our machines work with either plain strip up to 100mm wide, or pressed components, and can handle up to ¼ tonne.

When multiple, pallet mounted layer reels are used, they can process 500,000 parts per layer.

Figures provided depend upon variables such as the pitch between components, the complexity of components and the coating thickness required.

When you need selective electroplating, we can apply economical coatings of different metals in single or multiple stripes along the entire length of a reel. This can be a plain, part-blanked, or fully stamped component strip.

We can also spot plate using custom built tools to deposit gold or silver onto a specific component area, such as the critical contact surfaces of electrical connectors just 0.2mm diameter. For bandolier mounted pin type components, to minimise coating material use and cost, we can also ensure that only the outer contact surfaces are coated.

And if you need flexible circuit processing, we can process continuous rolls up to 600mm wide, which is far more cost-effective than transferring single sheets from bath to bath.

For complex 3D components, we use a 'contour plating' surface treatment to apply gold or silver metals. This is as selective as brush plating, but has the advantage of positive masking, a higher deposition rate and none of the problems usually associated with brush heads.

To learn more about how Auric’s advanced reel to reel plating technology can save you money and resources please contact us.